How tabular alumina use to produce refractory bricks

Here’s a detailed explanation of how **tabular alumina** is used to produce **refractory bricks**, including the production process, key properties, and applications:

—

### **Overview of Tabular Alumina in Refractory Bricks**

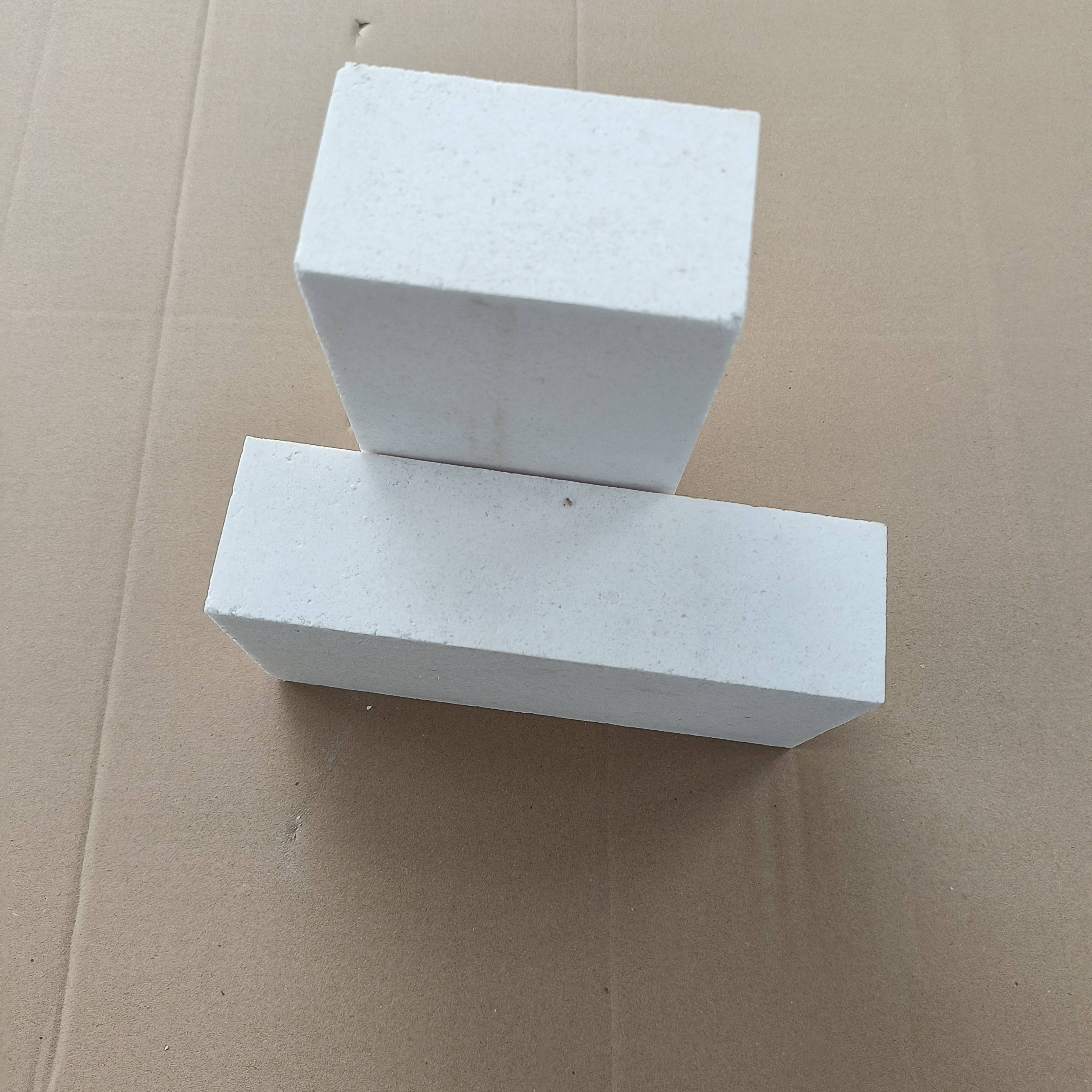

**Tabular alumina** (≥99% Al₂O₃) is a high-purity, sintered alpha-alumina aggregate with low porosity, high thermal stability, and excellent mechanical strength. It is a preferred raw material for manufacturing advanced refractory bricks used in extreme-temperature environments (e.g., furnaces, kilns, reactors).

—

### **Production Process of Tabular Alumina Refractory Bricks**

| **Step** | **Description** |

|————————-|————————————————————————————————–|

| **1. Raw Material Prep** | – **Tabular alumina** is crushed/screened into graded aggregates (coarse, medium, fine particles).<br>- Mixed with binders (e.g., calcium aluminate cement, phosphates) and additives (e.g., clays, microsilica). |

| **2. Mixing** | – Aggregates, binders, and water are homogenized to form a moldable batch.<br>- Particle size distribution is optimized for dense packing. |

| **3. Forming** | – The mixture is shaped into bricks via:<br> – **Pressing** (hydraulic press for high-density bricks).<br> – **Extrusion** (for complex shapes).<br> – **Casting** (slurry poured into molds). |

| **4. Drying** | – Green bricks are dried at 100–200°C to remove moisture and prevent cracking during firing. |

| **5. Firing** | – Bricks are sintered in high-temperature kilns (1600–1800°C).<br>- Binders react to form a ceramic bond, locking tabular alumina grains into a dense, monolithic structure. |

| **6. Quality Control** | – Bricks are tested for density, porosity, compressive strength, and thermal shock resistance. |

—

### **Key Properties of Tabular Alumina Bricks**

1. **High Temperature Resistance**: Stable up to 1800°C.

2. **Thermal Shock Resistance**: Low thermal expansion prevents cracking during rapid heating/cooling.

3. **Chemical Inertness**: Resists corrosion from molten metals, slags, and alkalis.

4. **Mechanical Strength**: High compressive strength (>100 MPa) due to dense microstructure.

5. **Low Porosity**: <15% porosity minimizes slag penetration.

—

### **Applications of Tabular Alumina Bricks**

– **Steel Industry**: Lining ladles, tundishes, and electric arc furnaces.

– **Glass Industry**: Tank furnaces, regenerators, and burner blocks.

– **Cement Industry**: Rotary kiln transition zones and burners.

– **Petrochemical Industry**: Reactors and reformers in refineries.

– **Non-Ferrous Metals**: Aluminum smelting furnaces and crucibles.

—

### **Advantages Over Traditional Refractories**

| **Feature** | **Tabular Alumina Bricks** | **Traditional Fireclay Bricks** |

|————————–|————————————————|———————————————|

| **Al₂O₃ Content** | ≥99% | 40–50% |

| **Max Service Temp** | ~1800°C | ~1400°C |

| **Thermal Shock Resistance** | Excellent | Moderate |

| **Slag Resistance** | High (inert to acidic/basic slags) | Low (reacts with basic slags) |

| **Lifespan** | 2–3x longer in harsh environments | Shorter, frequent replacements needed |

—

### **Why Tabular Alumina?**

– **Cost vs. Performance**: Higher upfront cost but superior durability reduces downtime and replacement frequency.

– **Customization**: Grain sizes and binder systems can be tailored for specific industrial needs.

– **Sustainability**: Longer lifespan reduces waste and resource consumption.

—

### **Challenges**

– **High Energy Use**: Firing requires significant energy input.

– **Brittleness**: Requires careful handling during installation.

—

In summary, tabular alumina refractory bricks are engineered for extreme conditions, combining high purity, thermal stability, and mechanical strength. Their production leverages the unique properties of tabular alumina to create durable, high-performance linings for industries demanding reliability at ultra-high temperatures. Let me know if you need further specifics!